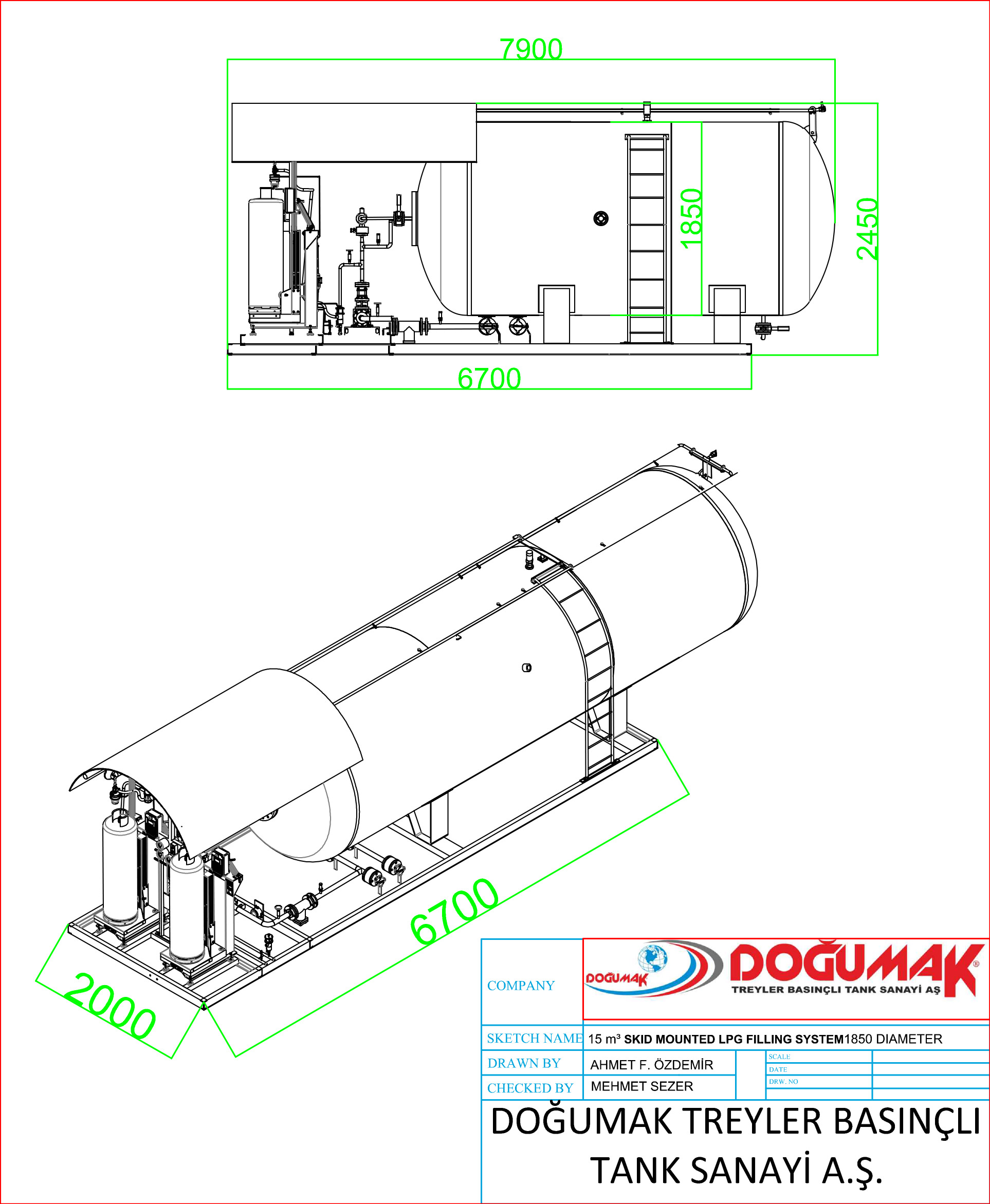

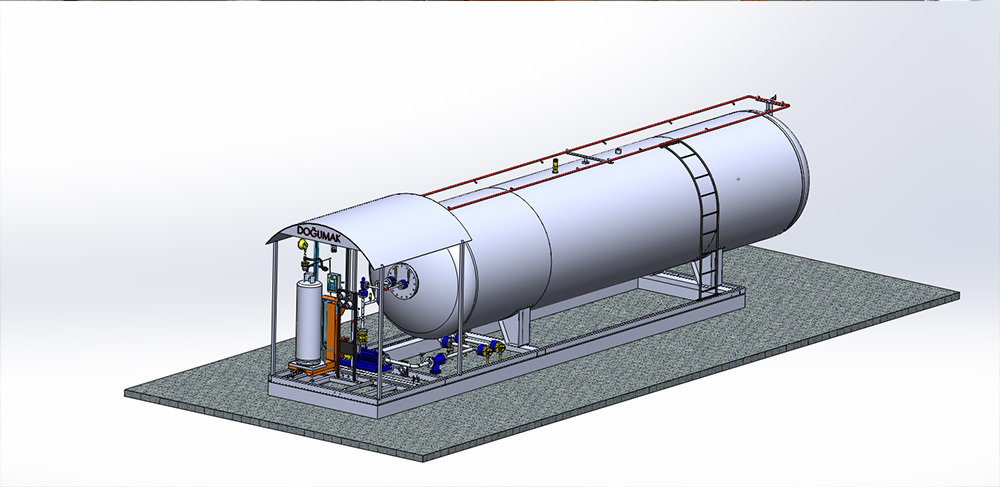

LPG CYLINDER FILLING SYSTEMS (SKID SYSTEMS)

We manufacture according to ADR, TPED, EN 12252, EN 12493, ASME CODE , 2014/68/EU standards

GeNERAL SPECIFICATIONS

DESIGN TEMPERATURE: –20°C / +50°C

DESIGN PRESSURE: 17,16 bar

Test PRESSURE: 26,5 bar

CAMBER TYPE: Eliptik

SPECIFICATIONS OF LPG CYLINDER FILLING SYSTEMS (SKID SYSTEMS)

- System is ready to use. Only the electrical connections are made and push the button. So it is extremely easy to use..

- Includes all necessary connection equipment.

- Can be transported anywhere.

- All electrical accessories are ex-proof.

- All equipments complies with EU standards and is CE certified

- ''P'' series pressure vessel carbon steel is used in our tanks

- Conforming to standards stress relieving elliptical KBS brand camber is used in tanks manufacturing

- Manufacturing and quality processes are produced in accordance with standards and procedures by our expert, experienced engineer staff.

- Testing is carried out by independent inspection body TUV.

- Welding process is carried out by certified welders with materials and methods according to standards.

- Tests and controls of all welded joints are carried out by certified NDT companies which are competent in their fields and have international validity

- All tanks are subjected to hydrostatic pressure test after manufacturing.

- Tank exterior surfaces are cleaned by grit blasting method with SA2,5 quality before painting.

- Painting

- • First coat Shop primer painting,

- • At least double coat epoxy coating painting,

- • CABIN PAINTING applying with double coat acrylic painting

- • bWith the improved technical equipment, homogeneous distribution to every point on the body and surface gloss in varnish paint gloss